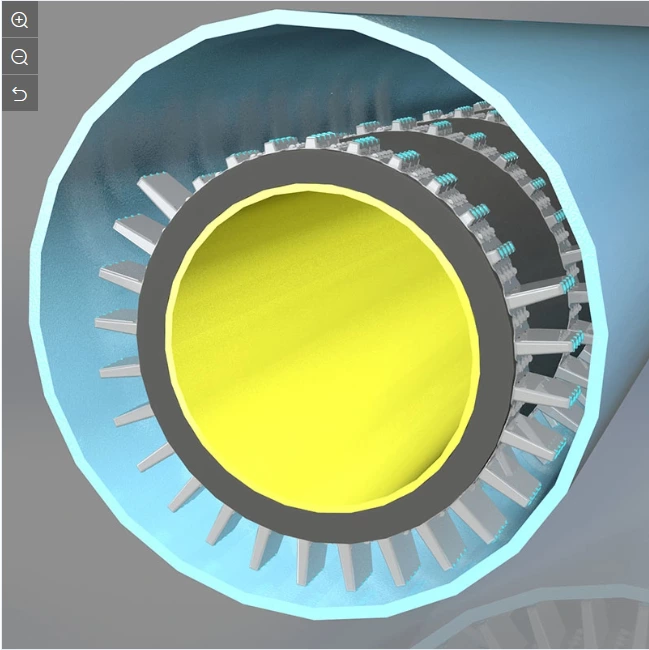

Casing Spacers HDPE with Wheel Runner for Pipe 400mm and Above

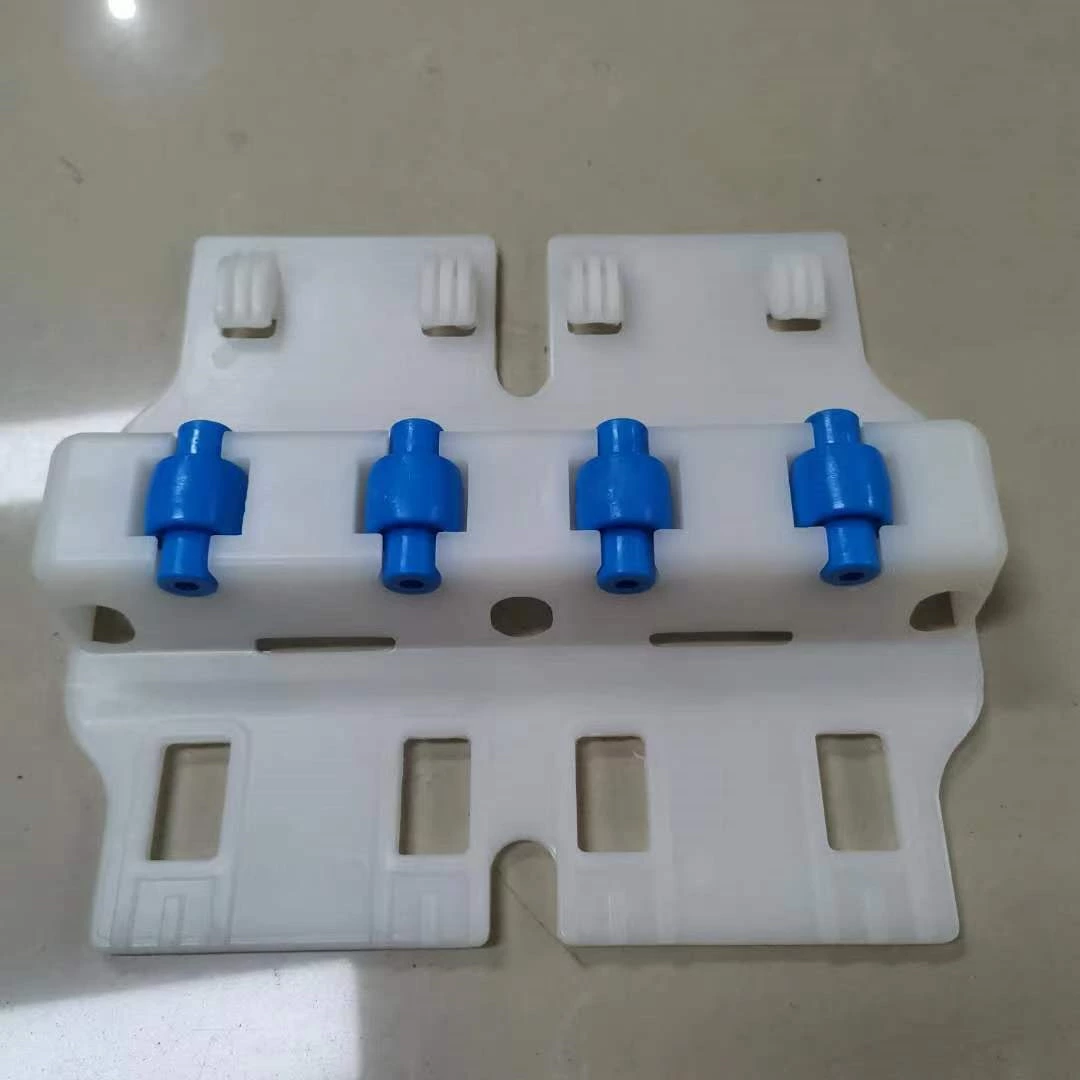

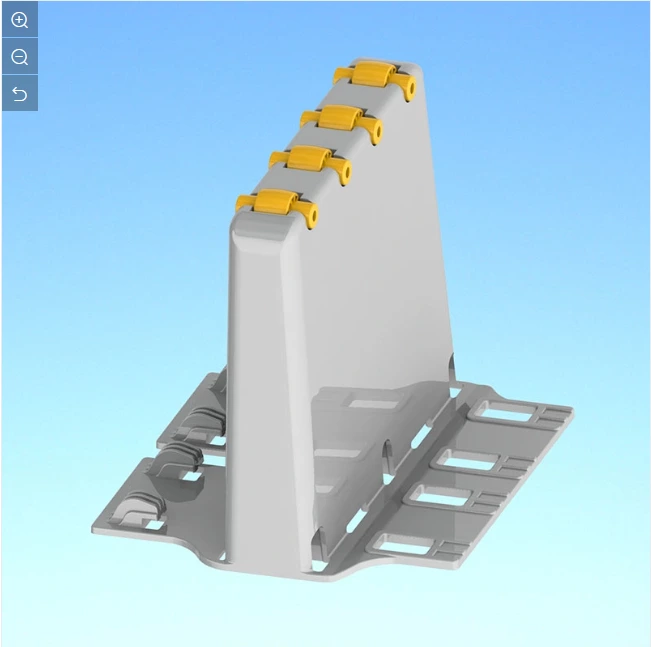

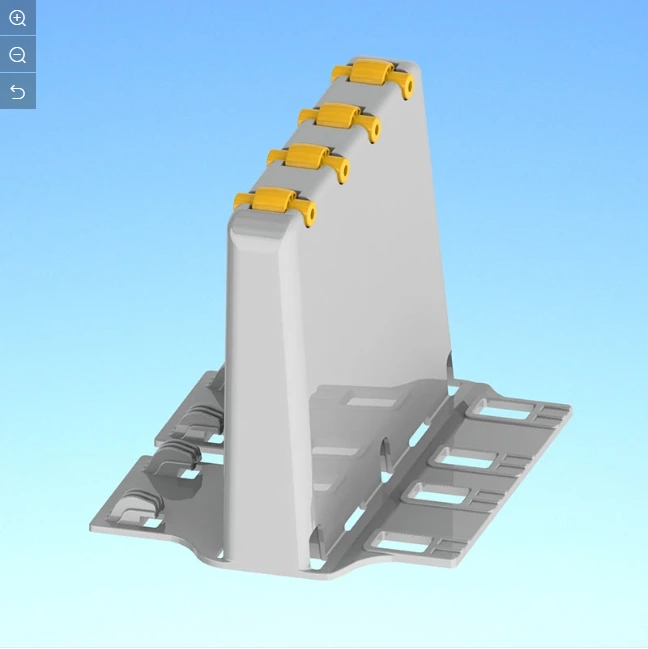

The skid spares are designed to protect pipes against the casing pipe during the pipeline go through railway, high way and constructions. The spacers are made from HDPE and fastened by nylon screws so that to devoid metal material.The runners have wheels on top and decrease the friction and allow the carrier pipe to travel through a casing with less resistance.

- Mould Time

- 7-15 days

- Product time

- 7-20 days

- Moud precision

- +/-0.01mm

- Mould life

- 500,000 shots

- Material

- HDPE

- Size

- As customized

- Package

- carton or as requirement

- MOQ

- no limited

Installation Instructions

How to install the runners to the tube?

- Prepare appropriate number of elements and connect them by means of clips.

- Impose circuit on the carrier pipe.

- translate through the side openings extreme skids nylon screws and washers and nuts.

- Move the circuit at the required place,

- Tighten the nuts evenly causing a tightening of the runners on the tube,

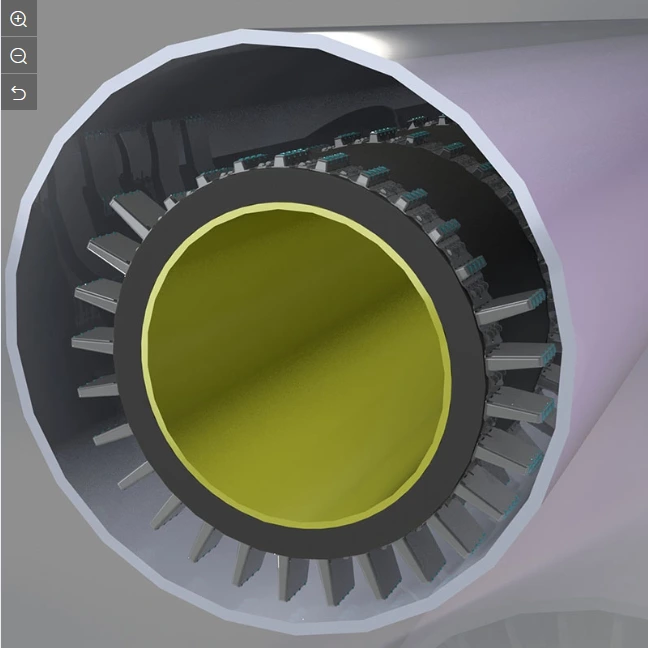

- After the establishment of the required number of circuits to be the conduit inserted into the casing pipe.

Our Advantages

APPLICATIONS

Placement of carrier pipes through casing. Casing spacers supported and positioned pipe inside a casing pipe.

Casing Insulators prevent damage to the outer coated surface of a pipeline during installation.

GENERAL FEATURES

Easy Installation: wheel rollers provide minimal coefficient of friction allowing the carrier pipe to more easily pulled through the casing.

Cathodic Protection: with low moisture absorption of the polyethylene material.

Casing Spacers with wheel rollers - NO METAL PARTS

Use two spacers back to back at the leading edge + 1.5m spacing along the pipe bore.

Nylon closing bolts

Material: HDPE

Runner Width 240 mm

Leg lengths: 32, 50, 70, 100, 160 mm, 210 mm

Casing spacer models have four wheel runners to support heavy loads. Insert forces are reduced by the roller wheels.

Casing spacers for pipe through casing or ducts, position the carrier pipe in the casing with specific leg heights.

The non-conductive wheel runners provide cathodic protection.