Custom Online CNC Machining Services

- Instant CNC online quotes

- Free & Automatic DFM feedback

- Tolerances down to 0.0004 (0.01mm)

- Machined parts as fast as 1 day

To complete large-volume manufacturing requirements, take advantage of our plastic injection molding, sheet metal fabrication, and other production processes.

For batch manufacturing, we have several options to accommodate your requirements, like vacuum casting, CNC machining, and plastic injection molding.

We use the latest technology and equipment to produce prototypes quickly and accurately, helping clients to reduce their product development time and costs.

Request your quote from our online quotation platform and our dedicated engineers will provide a response within 24 hours, ensuring the process goes on smoothly.

To ensure we can produce functional molds, we offer feasibility reviews of your design to ensure we can fulfill requirements before starting production.

Predictive modeling software helps us look at the way molten material moves and acts within the mold, which helps us deliver improvements.

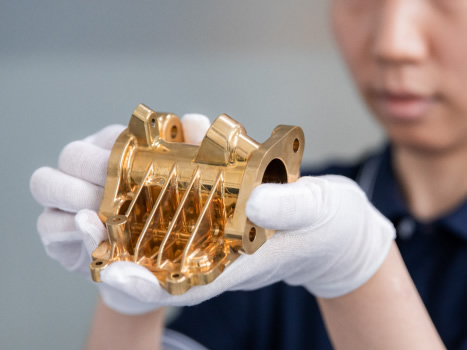

Start the production of mold tooling according to your specific application needs by using the materials and finishs of your choice.

T1 sampling will be delivered for you to review prior to manufacturing plastic parts to ensure precision and quality.

After completing the trial production phase, we proceed to low volume production, utilizing advanced machining techniques to manufacture parts quickly and efficiently.

A strict inspection process, including the inspection of function, dimension, and appearance, ensures that the parts meet the required specifications and are of high quality.

After a thorough inspection, we will deliver your products to you as quickly as possible while ensuring their safety.

ABS

Acetal/Delrin

Acrylic

CPVC

CTFE/KEL-F

Delrin AF

ECTFE (Halar)

LDPE

Fluorosint (500 and 207)

PPS

PVDF

PVC

Radel®

Tecadur

Teflon

Torlon (4203 and 4301)

Uhmw

Ultem

Vespel

Noryl

Nylon 6/6

PBT

Peek

PES (Radel A)

PET

Phenolics/g10

Polycarbonate

Polypropylene

Polysulfone

We hope you can provide detailed information about your needs, usage scenarios, and specific requirements, so that we can better understand and provide customized solutions for you.

We provide comprehensive after-sales service, including technical support, troubleshooting and repair, training, and knowledge transfer. Our goal is to ensure that customers receive the best experience and value when using our products. If you have any questions or need assistance, please feel free to contact our after-sales team, and we will be happy to provide you with support and solutions.